According to the different functions of the oil purifier, it can be divided into:

A. Oil purifier for filtering impurities, such as plate and frame oil purifier, filter dispenser, automatic slag oil purifier, bag oil purifier.

B. Oil purifier for filtering impurities, moisture and gas, such as vacuum oil purifier and bag oil purifier.

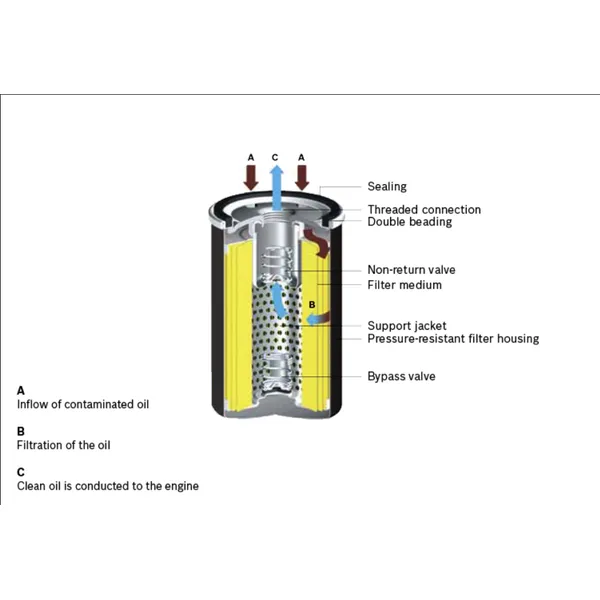

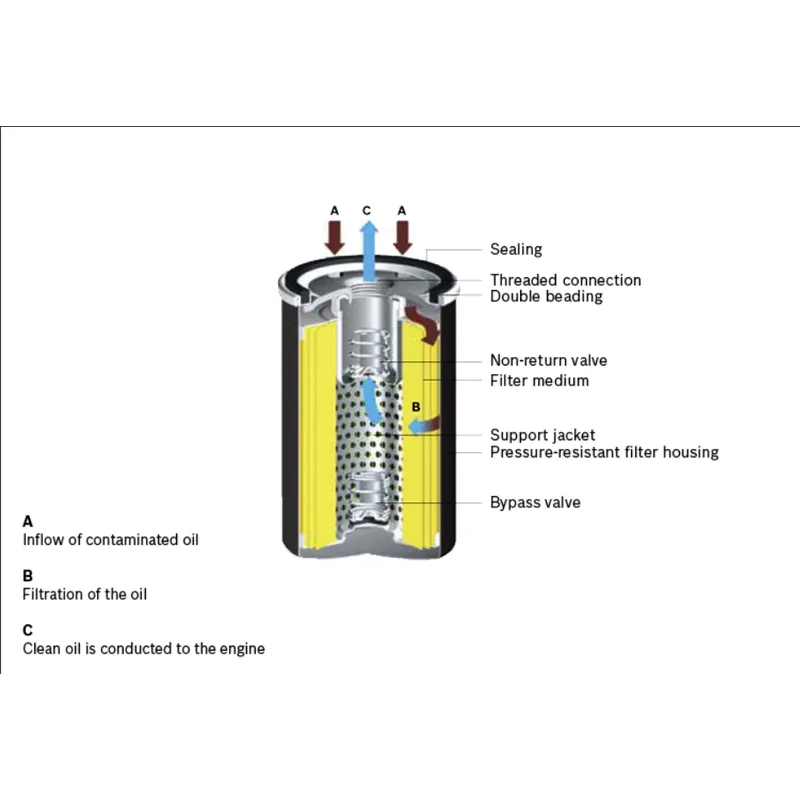

The oil purifier filters mechanical impurities and metal powder and other harmful substances in the oil, generally using the method of physical filtration, and the working principle is: the oil is pressurized by the oil pump through the primary filtration and outlet fine filtration to complete the filtration process. The primary filter element adopts stainless steel corrugated filter element, which can be used repeatedly after cleaning, reducing the operating cost and saving consumption.

The fine filter element adopts imported glass fiber filter material, which has the advantages of high filtration accuracy, strong oil transmission ability, small original pressure, and large dirt holding capacity, but the fine filter element is blocked and cleaned more difficult, so it needs to be replaced according to the pressure difference display.